Detection of Gold, Silver and Copper in Waste Liquid

1 Sample solution preparation:

2 Experimental equipment and reagents:

3 Instrument conditions

[Graphite furnace temperature curve]

4 Standard solution preparation

5 Standard curve

After Ag and Cu were acidified with 1% nitric acid, they were introduced directly tested into the machine for testing;

Au: 25 mL sample solution was weighed and placed in a beaker, heated on hot place to reduce to a small volume, and cooled down. 40 mL (1:1) aqua regia, 1 mL 20% iron trichloride were added, the beaker was shaken, and then heated on a hot plate. As the solution left was about 10mL, it was diluted to 40mL in volume with deionized water, added with the soaked sponge (soaked in 5% hydrochloric acid overnight, the volume is 1*1*2), covered with stopper, and shaken on a shaker for 30min. The sponge was removed and rinsed to neutral with deionized water, squeezed dry, placed into a 10 mL colorimetric tube pre-filled with 1% thiourea. The sponge was completely immersed in the thiourea solution, and kept in boiling water bath for 30 minutes. Then, the sponge was removed, cooled down to room temperature. It was then introduced into the graphite furnace machine for testing. Same treatment was performed for standard curve.

Au: 25 mL sample solution was weighed and placed in a beaker, heated on hot place to reduce to a small volume, and cooled down. 40 mL (1:1) aqua regia, 1 mL 20% iron trichloride were added, the beaker was shaken, and then heated on a hot plate. As the solution left was about 10mL, it was diluted to 40mL in volume with deionized water, added with the soaked sponge (soaked in 5% hydrochloric acid overnight, the volume is 1*1*2), covered with stopper, and shaken on a shaker for 30min. The sponge was removed and rinsed to neutral with deionized water, squeezed dry, placed into a 10 mL colorimetric tube pre-filled with 1% thiourea. The sponge was completely immersed in the thiourea solution, and kept in boiling water bath for 30 minutes. Then, the sponge was removed, cooled down to room temperature. It was then introduced into the graphite furnace machine for testing. Same treatment was performed for standard curve.

2 Experimental equipment and reagents:

AA7000 series atomic absorption spectrophotometer (with Ag, Cu, Au hollow cathode lamp, EWAI Inc.)

Hot plate

Iron trichloride: analytical grade purity

Hydrochloric acid: excellent grade purity

Nitric acid: excellent grade purity

Gold standard solution (National Reference Materials Research Center)

Silver standard solution (National Reference Materials Research Center)

Copper standard solution (National Reference Materials Research Center)

Hot plate

Iron trichloride: analytical grade purity

Hydrochloric acid: excellent grade purity

Nitric acid: excellent grade purity

Gold standard solution (National Reference Materials Research Center)

Silver standard solution (National Reference Materials Research Center)

Copper standard solution (National Reference Materials Research Center)

3 Instrument conditions

| Parameter | Wavelength (nm) |

Slit Width(nm) | Burner height(mm) | Fuel gas flow rate(L/min) | Lamp current(mA) | Flame type |

| Cu | 324.7 | 0.2 | 10 | 1.5 | 3 | Air - acetylene |

| Ag | 328.1 | 0.2 | 10 | 1.5 | 3 | Air - acetylene |

| Element | Wavelength (λ/nm) |

Lamp current (I/mA) |

D2 lamp current(I/mA) | Spectral bandpass width(△λ/nm) | Background correction technique |

| Au | 242.8 | 2 | 100 | 0.2 | D2 lamp |

[Graphite furnace temperature curve]

| No | Step | Start temp (℃) | End temp (℃) | Heating time (s) | Inner gas path | Auxiliary gas path | Mode | Alarm |

| 1 | Drying | 40 | 100 | 20 | Open | Off | Power | On |

| 2 | Drying | 100 | 120 | 10 | Open | Off | Power | On |

| 3 | Ashing | 120 | 300 | 50 | Open | Off | Power | On |

| 4 | Ashing | 300 | 600 | 8 | Open | Off | Power | On |

| 5 | Ashing | 600 | 600 | 6 | Off | Off | Power | |

| 6 | Atomization | 2500 | 2500 | 3 | Off | Off | Power | On |

| 7 | Cleaning | 2600 | 2600 | 3 | Open | Off | Power | |

| 8 | Cooling | 0 | 0 | 22 | Open | Off | Power | |

| 9 | Cooling | 0 | 0 | 1 | Off | Off | Power | On |

4 Standard solution preparation

| Element | Concentration | |||||

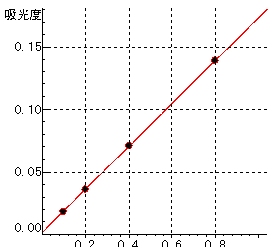

| Cu(μg/mL) | 0 | 0.1 | 0.2 | 0.4 | 0.8 | |

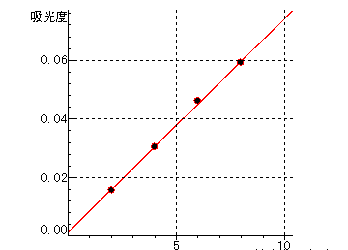

| Au(μg/L) | 0 | 2.0 | 4.0 | 6.0 | 8.0 | |

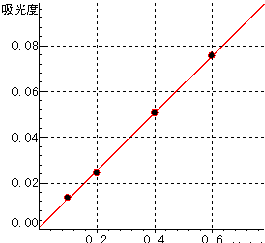

| Ag(μg/mL) | 0 | 0.1 | 0.2 | 0.4 | 0.6 | |

5 Standard curve

Concentration (mg/L) Concentration (mg/L)Ag Linearity coefficient:0.99970 Curve equation:Y=0.12512*X+0.00059 |

Concentration (μg/L) Au Linearity coefficient:0.99950 Curve equation:Y=0.00732*X+0.00125 |

Concentration (mg/L) Cu Linearity coefficient:1.00000 Curve equation:Y=0.17222*X+0.0014 |

|