Detection of Thallium Content in Wastewater Lead Block

1 Sample solution preparation:

2 Experimental equipment and reagents:

3 Instrument conditions

4 Standard solution preparation

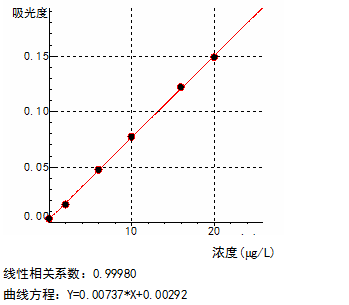

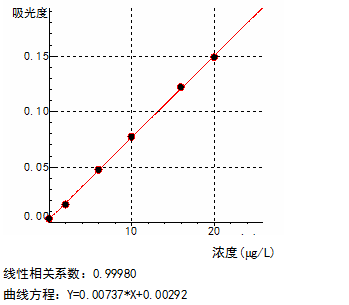

5 Standard curve

Curve equation : Y=0.00737*X+0.00292

Linearity coefficient : 0.99980

1.1 Water sample could be introduced into the machine directly.

1.2About 1.0g sample (precision to one-ten-thousandth) was weighed and placed in a conical flask, 15mL 10% nitric acid was added, covered with lid, heated at lower temperature on hot place to digest the sample. After digestion, it was removed for cooling, then the cup wall was rinsed with deionized water, heated on the hot plate to reduce the acid to about 5mL, transferred into a 25mL volumetric flask, rinsed at least 3 times with deionized water. Then, it was diluted and made up to the volume to volume, spared for later use.

1.2About 1.0g sample (precision to one-ten-thousandth) was weighed and placed in a conical flask, 15mL 10% nitric acid was added, covered with lid, heated at lower temperature on hot place to digest the sample. After digestion, it was removed for cooling, then the cup wall was rinsed with deionized water, heated on the hot plate to reduce the acid to about 5mL, transferred into a 25mL volumetric flask, rinsed at least 3 times with deionized water. Then, it was diluted and made up to the volume to volume, spared for later use.

2 Experimental equipment and reagents:

AA7000 series atomic absorption spectrophotometer (with Tl hollow cathode lamp, EWAI Inc.)

Temperature-controlled hot plate

Conical beaker

Nitric acid (HNO3): excellent grade purity

Thallium standard solution (National Reference Materials Research Center)

Temperature-controlled hot plate

Conical beaker

Nitric acid (HNO3): excellent grade purity

Thallium standard solution (National Reference Materials Research Center)

3 Instrument conditions

| Element | Wavelength (λ/nm) |

Lamp current (I/mA) |

D2 lamp current(I/mA) | Spectral Bandpass width(△λ/nm) | Background correction technique |

| Tl | 276.8 | 2 | 100 | 0.2 | 氘灯 D2 lamp |

[Graphite furnace temperature curve]

| No | Step | Start temp (℃) | End temp(℃) | Heating time (s) | Inner gas path | Auxiliary gas path | Mode | Alarm |

| 1 | Drying | 40 | 100 | 30 | Open | Off | Power | Open |

| 2 | Drying | 100 | 120 | 10 | Open | Off | Power | Open |

| 3 | Ashing | 120 | 600 | 10 | Open | Off | Power | Open |

| 4 | Ashing | 600 | 600 | 8 | Open | Off | Power | Open |

| 5 | Ashing | 600 | 600 | 6 | Off | Off | Power | Open |

| 6 | Atomization | 2700 | 2700 | 3 | Off | Off | Power | Open |

| 7 | Cleaning | 2700 | 2700 | 3 | Open | Off | Power | Open |

| 8 | Cooling | 0 | 0 | 22 | Open | Off | Power | Open |

| 9 | Cooling | 0 | 0 | 1 | Off | Off | Power | Open |

4 Standard solution preparation

| Element | Concentration | ||||

| Tl(μg/L) | 0 | 2.0 | 6.0 | 10.0 | 20.0 |

Curve equation : Y=0.00737*X+0.00292

Linearity coefficient : 0.99980