Trace Au Analysis in Reference Materials

1 Sample solution preparation:

2 Experimental equipment and reagents:

3 Instrument conditions

Au graphite furnace heating program

4 Standard solution preparation

5 Standard curve

(1)10.0g GAu-9b sample and 5.0g GAu-13a sample were weighed and placed separately in 40 mL porcelain crucible, and burned at 650 °C for 1 h, and then removed for cooling. The cooled sample was transferred to a 250 mL flask, wet with small amount of water, about 40mL freshly prepared 1:1 aqua regia (HCl:HNO3=3:1) was added, the flask was shaken by hand to disperse sample in solution. 1mL iron trichloride was added (if iron trichloride is not well dissolved, add 1% hydrochloric acid), heated on a hot plate to digest sample. When digestion is up to about 10mL in volume, it was removed from hot plate.

(2)It was diluted to about 100 mL in volume with purified water, added with a sponge that has been soaked overnight with 5% hydrochloric acid, covered with a stopper, shaken on a shaker for 30 min. Then the sponge was removed and rinsed with deionized water until neutral, squeezed dry. 5mL 1% thiourea (10g / L) was placed in colorimetric tube, and the sponge was soaked completely in the thiourea solution, kept inside boiling water bath for 30min. The sponge was then removed, cooled to room temperature, spared for later use.

Standard solution preparation should also be performed according to step 2.

Standard solution preparation should also be performed according to step 2.

2 Experimental equipment and reagents:

AA7000 series atomic absorption spectrophotometer (with Pd hollow cathode lamp, EWAI Inc.)

Muffle furnace

Temperature-controlled hot plate

Variable speed oscillator

Nitric acid (HNO3): excellent grade purity

Hydrochloric acid (HCl): excellent grade purity

Iron chloride (FeCl3): excellent grade purity

Thiourea (CH4N2S): analytical grade purity

Gold standard solution (National Reference Materials Research Center)

Muffle furnace

Temperature-controlled hot plate

Variable speed oscillator

Nitric acid (HNO3): excellent grade purity

Hydrochloric acid (HCl): excellent grade purity

Iron chloride (FeCl3): excellent grade purity

Thiourea (CH4N2S): analytical grade purity

Gold standard solution (National Reference Materials Research Center)

3 Instrument conditions

| Element | Wavelength (λ/nm) |

Lamp current (I/mA) |

D2 lamp current (I/mA) |

Spectral bandpass width(△λ/nm) | Background correction technique |

| Au | 242.8 | 1.3 | 80 | 0.2 | D2 lamp |

| Id | Step | Start temp | End temp | Heating time | Inner gas path | Auxiliary gas path | Mode |

| 1 | Drying | 50 | 120 | 40 | Open | Off | Power |

| 2 | Drying | 120 | 120 | 10 | Open | Off | Power |

| 3 | Ashing | 120 | 500 | 10 | Open | Off | Power |

| 4 | Ashing | 500 | 500 | 8 | Open | Off | Power |

| 5 | Ashing | 500 | 500 | 3 | Off | Off | Power |

| 6 | Atomization | 2400 | 2400 | 4 | Off | Off | Power |

| 7 | Cleaning | 2500 | 2500 | 2 | Open | Off | Power |

| 8 | Cooling | 0 | 0 | 30 | Open | Off | Power |

| 9 | Cooling | 0 | 0 | 1 | Off | Off | Power |

4 Standard solution preparation

| Elemet | Concentration(ng/mL) | |||||

| Au | 0 | 0.5 | 1.0 | 3.0 | 5.0 | |

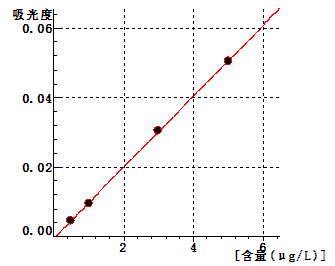

5 Standard curve

Au Curve equation:y=0.0102*x-0.0005 Linearity coefficient:0.99992 |